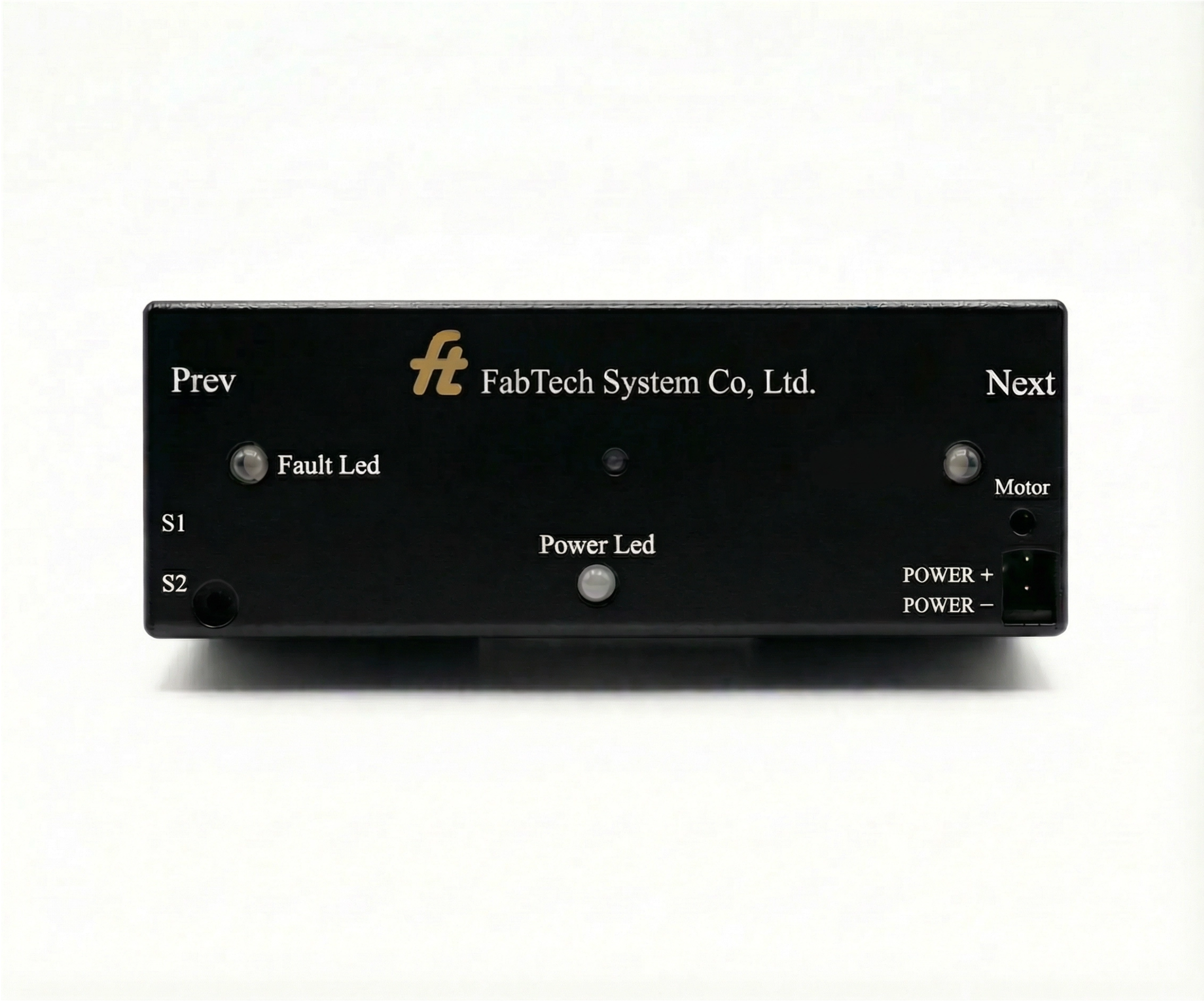

Non-PLC

Controller System

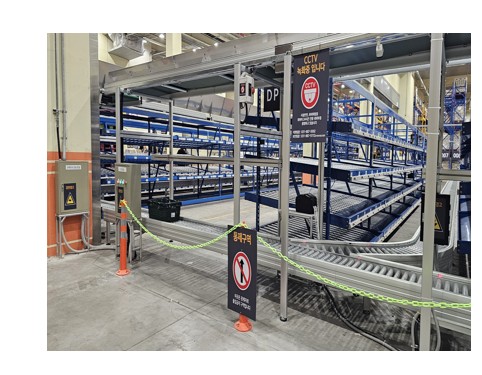

Smart motion control solution without PLC.

Easy installation and expansion with serial daisy-chain connection.

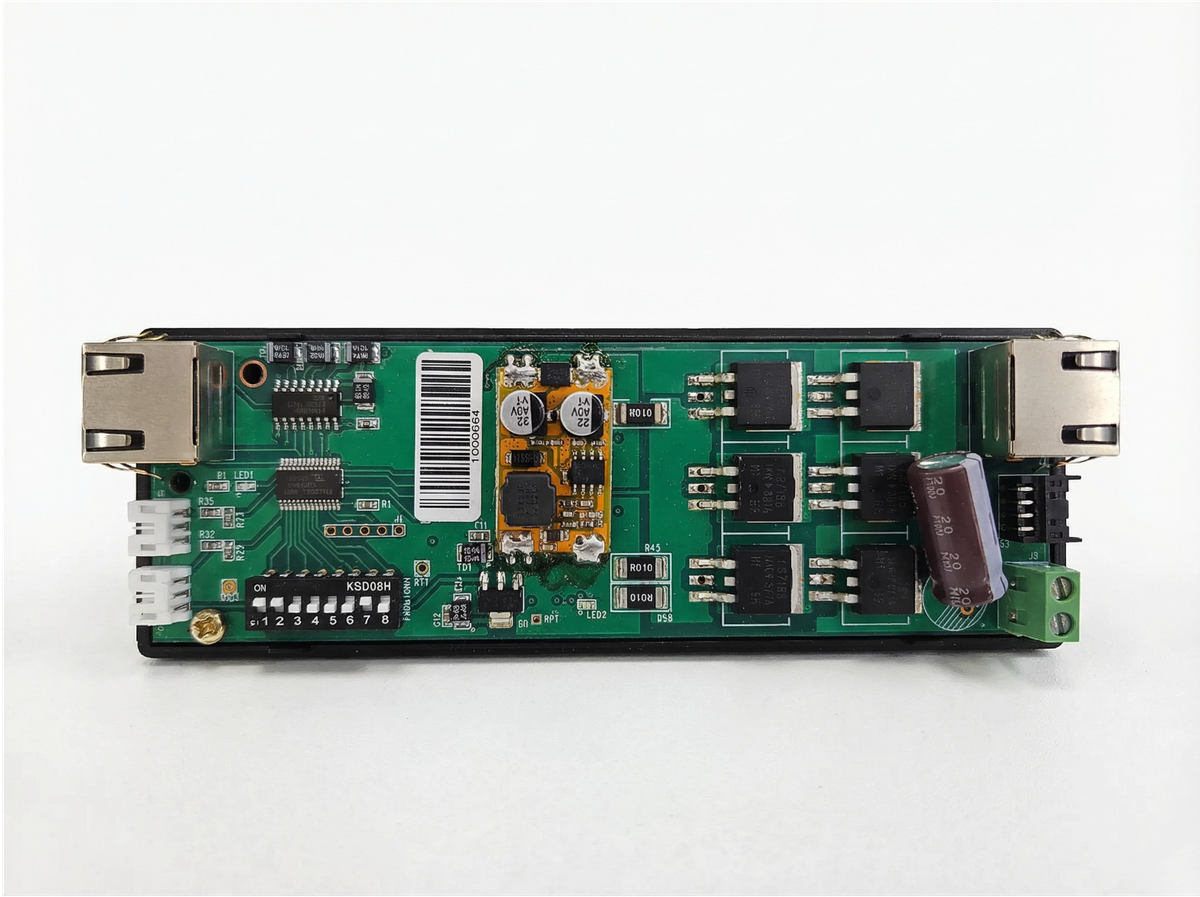

Motor Controller

Individual Motor Control

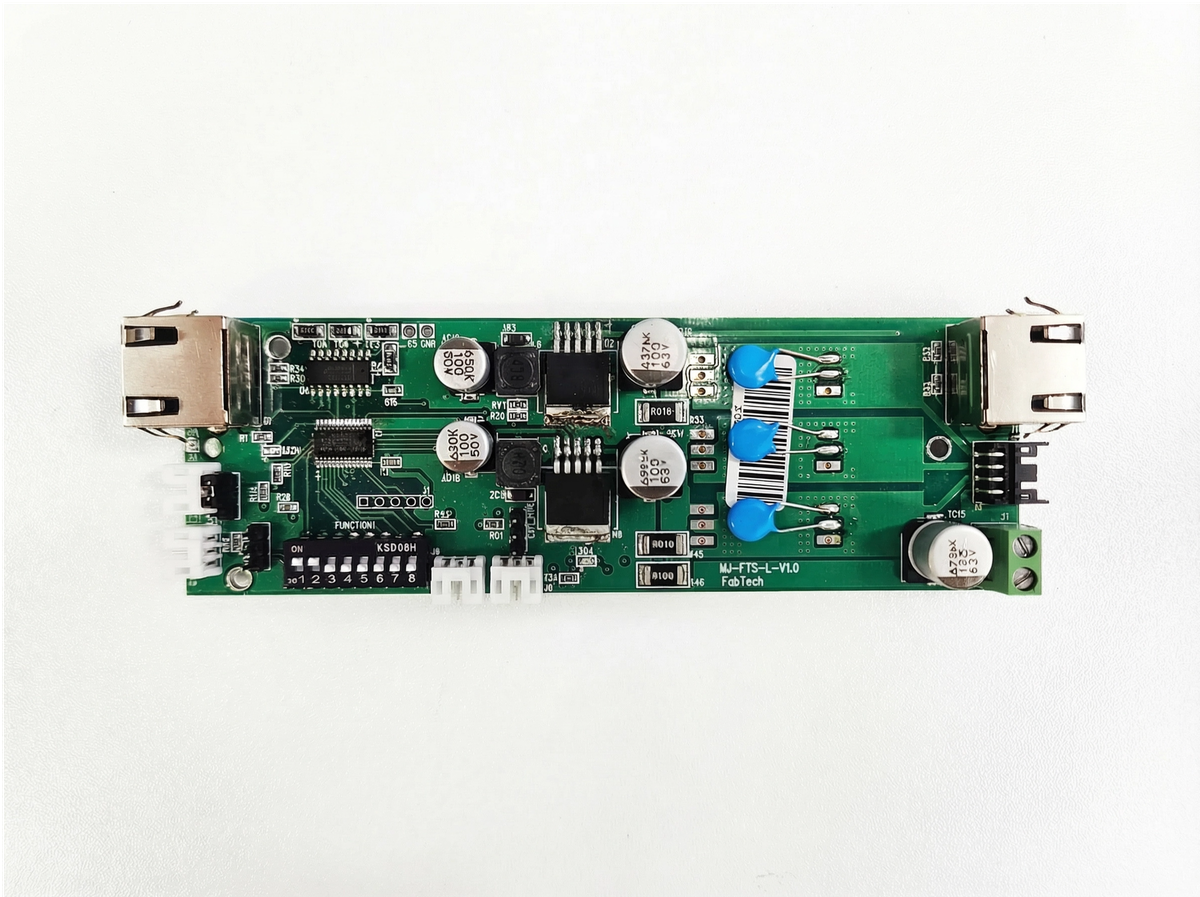

Hub

Communication Hub